Wellcraft, V20 and Steplift remain the property of the Wellcraft Company

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Operation "Hatch Repair" underway

- Thread starter frayed_knot

- Start date

Skools Out

God

um hello that resin is thick and not that cheap crap from boaters world , if that hatch is like my 78 you can't put the wood side down the lip is thicker than the wood. Frayed you did good no issues now get on the water but pick me up inEI while out cruising ;D

frayed_knot

Senior Member

Well, I'm all set to reinstall the cover tomorrow. I spent $50 at Lowes getting some silicone and stainless hardware to do the phatdaddy method of hatch securing. I actually found the tee-nuts in stainless, but they ain't cheap, $4.97 for 2  I'm gonna use 4200 to stick the blocks in place ( cuz that's what I got

I'm gonna use 4200 to stick the blocks in place ( cuz that's what I got  ) I figure I'll clamp them in place until the 4200 sets up a little then put the cover on and tighten the screws, that'll hold her down. I went all over New Bern looking for some self etching primer for the fuel tank. I finally found some at Auto Zone. It's a hideous green color, but who cares.

) I figure I'll clamp them in place until the 4200 sets up a little then put the cover on and tighten the screws, that'll hold her down. I went all over New Bern looking for some self etching primer for the fuel tank. I finally found some at Auto Zone. It's a hideous green color, but who cares.

frayed_knot

Senior Member

OK, sounds good, thanks phat.

Weird to say phat by the way, on every other non-boat board I'm on, I'm Phatpony

Weird to say phat by the way, on every other non-boat board I'm on, I'm Phatpony

frayed_knot

Senior Member

Hey MJ, I thought about pretreating the wood, but I just couldn't find the info to substantiate doing that first. Next time I will do just that, but I will start in the morning and apply the second coat and cloth (depending on what I'm building / repairing) after the first coat gets tacky.

Skools Out

God

if you coat the wood first and it soaks in and dries your bond to the glass will be terrible and will come loose later, if you coat both heavily and bond together the resin soaks into the wood and cures to the glass as well and is bonded as 1 piece.

reelapeelin

God

Frayed, I hear what Phat's sayin' about puttin' the screws in B4 the 4200 cures, and admittedly it's a "rock and hard place" thing, but if you try startin' those screws w/ the 42 still wet, it'll be REEL easy to push the block away from it's intended location B4 the screw starts threading the nut ...it'll take a LIGHT touch ...

...another thing to consider...those T-Nuts do their job REEL well and will allow LOTS of torque ... take 'er easy when tightening or that fiberglass'll go to crackin' on ya ...

...

...anyway, hope ya "geeter-dun" quick ... it's time to SPLASH 8) ...

... it's time to SPLASH 8) ...

...another thing to consider...those T-Nuts do their job REEL well and will allow LOTS of torque ... take 'er easy when tightening or that fiberglass'll go to crackin' on ya

...anyway, hope ya "geeter-dun" quick

macojoe

Administrator

if you coat the wood first and it soaks in and dries your bond to the glass will be terrible and will come loose later, if you coat both heavily and bond together the resin soaks into the wood and cures to the glass as well and is bonded as 1 piece.

Gee you would think glass would stick to glass? Learn something new every day!! Thats why we call him Lord Skools!

frayed_knot

Senior Member

If'n one was to pretreat, you would have to apply the second coat within a certain time period, before cured, to make a good chemical bond. That's why it would need to be a morning start. Have to sit there with a beerskie touching the goo every so often so as not to miss the window of opportunity

So anyway, that's all water under the keel now. I'm done! I'm not the least bit happy with it though. Remember those unbonded pockets I referred to earlier? Well, they sound like I'm going to break the dang thing as I walk on it, snap crackle pop. Only where the bond isn't good. It seems plenty strong though, I can walk on it without it sagging. So that's good I guess. The Phatdaddy mod didn't work out so good for me either. Not what you would expect though. I went ahead and bonded the blocks of wood with the 4200, but instead of putting the lid on there, I eyeballed the alignment and drove the screws right in until it cured. That worked just fine. The problem came once I ran my bead of silicone all the way around the opening and set the lid in place. 3 out of the eight Tee nuts didn't stick into the wood!!!! As I put my screw in, they popped out the back side of the block. HOLY CRAP!!!! Well, I didn't pull the lid back up. Ta hell with it for now I needed to get it back together to take the family out tomorrow, and it's done enough for that. I'll post my pics later on after I have a chance to cool down.

I needed to get it back together to take the family out tomorrow, and it's done enough for that. I'll post my pics later on after I have a chance to cool down.

So anyway, that's all water under the keel now. I'm done! I'm not the least bit happy with it though. Remember those unbonded pockets I referred to earlier? Well, they sound like I'm going to break the dang thing as I walk on it, snap crackle pop. Only where the bond isn't good. It seems plenty strong though, I can walk on it without it sagging. So that's good I guess. The Phatdaddy mod didn't work out so good for me either. Not what you would expect though. I went ahead and bonded the blocks of wood with the 4200, but instead of putting the lid on there, I eyeballed the alignment and drove the screws right in until it cured. That worked just fine. The problem came once I ran my bead of silicone all the way around the opening and set the lid in place. 3 out of the eight Tee nuts didn't stick into the wood!!!! As I put my screw in, they popped out the back side of the block. HOLY CRAP!!!! Well, I didn't pull the lid back up. Ta hell with it for now

frayed_knot

Senior Member

Dat's what I'm talkin about!

reelapeelin

God

Bummer on the T-Nuts fallin' thru...happened to me B4, but I was able to get 'em...w/ no nut to hold 'em, just fill the hole w/4200 and seat the screw in there ... it'll look right and seal the hole ...that hatch-lid ain't goin' anywhere  ...

...

Can you tell exactly where the air-pockets are ... if so, drill 1/8th or so hole in the center of the pocket(this in the groove between non-skid), take a hypodermic syringe and inject the hole w/resin...let cure, then drill out just enough to hold some filler ... you'll never see 'em ...and the noise will go away 8) ...go enjoy the boat...ya did a good job ;D ;D ;D ...

;D ;D ;D ...

Do the above later on...take your family out and enjoy the weekend ;D ...

;D ...

Can you tell exactly where the air-pockets are ... if so, drill 1/8th or so hole in the center of the pocket(this in the groove between non-skid), take a hypodermic syringe and inject the hole w/resin...let cure, then drill out just enough to hold some filler ... you'll never see 'em ...and the noise will go away 8) ...go enjoy the boat...ya did a good job

Do the above later on...take your family out and enjoy the weekend

phatdaddy

God

sorry frayed, hope i didn't lead you astray. the tee nuts only get a grip when you sink them into the wood. i tapped mine in with a hammer to the blocks of wood about the size of a business card. gooped them with the 5200 and set them in place. then i lightly laid the deck plate on and got the screws started. once i got them all started i went around and tighten then like a head gasket. sorry if i messed you up

anyway, like mj & rap say, just go use it.......

anyway, like mj & rap say, just go use it.......

frayed_knot

Senior Member

Don't worry about it phat, it is a great idea and one that I will make work next time I have the lid off. I did tap them in with a hammer though, and they had pressure on them for a few hours. I have no idea why they did what they did. This winter I'll take those blocks back out and replace them with some blocks coated in resin. I'll make sure the tee nuts are resined in this time

frayed_knot

Senior Member

As promised, pics!

Here is the completed hatch cover. I had to replace the deck plates and could only find white ones. It works.

The fuel tank after it's new coat of primer

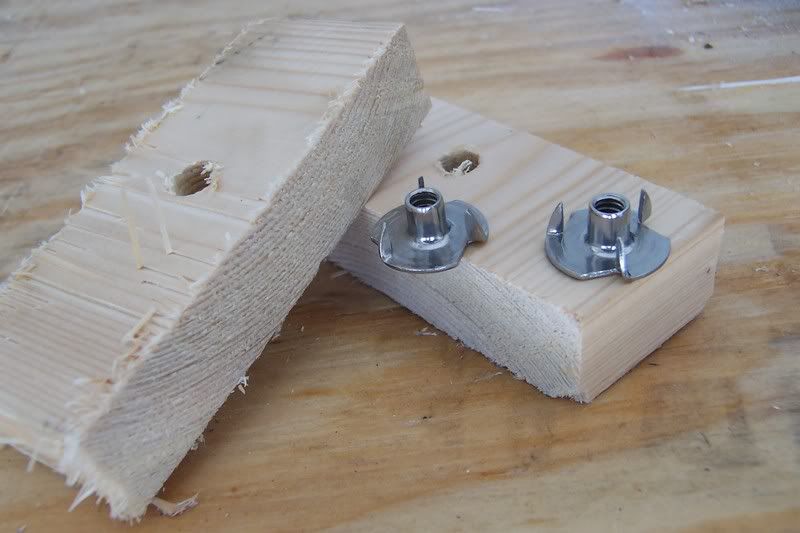

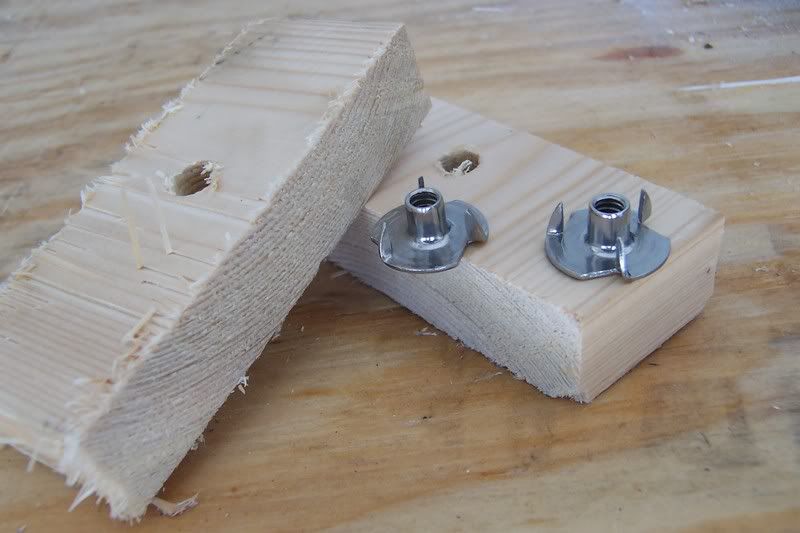

The Tee nuts

Here is the completed hatch cover. I had to replace the deck plates and could only find white ones. It works.

The fuel tank after it's new coat of primer

The Tee nuts

frayed_knot

Senior Member

Here is how I mounted them while waiting for the 4200 to setup

The two at the very front I had problems with. The way the holes were drilled put them too close to the front bulkhead so the block of wood couldn't be mounted up there. Here you can see where the bulkhead is. I drilled 2 new holes and mounted the blocks farther aft.

Here is the completed ( ? ) project. The silicone was skinning up real quick, so I had to fill the cracks and smooth them out in sections.

The two at the very front I had problems with. The way the holes were drilled put them too close to the front bulkhead so the block of wood couldn't be mounted up there. Here you can see where the bulkhead is. I drilled 2 new holes and mounted the blocks farther aft.

Here is the completed ( ? ) project. The silicone was skinning up real quick, so I had to fill the cracks and smooth them out in sections.

Skools Out

God

looks great pick me up lets fish. ;D

frayed_knot

Senior Member

Aiight!! ;D

There was a 17 lb striper caught in New Bern this week!!! Probably one of the biggest ever caught in the Neuse river.

There was a 17 lb striper caught in New Bern this week!!! Probably one of the biggest ever caught in the Neuse river.