Previously I have posted the failure of my power head and have since replace it with a rebuild which by the way is working great.

I traded two older motors at the time with PowerHead Exchange out of Tampa and kept my blown power-head with this project in mind.

I will start rebuilding/assembly it from prop up. Trust me this is going to be long term project or if the 49ers sucks on Sundays then it will progress faster.

The objective is to apply what I have learned and hopefully own a engine I can be proud of, I have done my home work in regards to acquiring the parts and everything plus sum for this project.

This weekend I hit jackpot with an identical year/make/model motor minus power head (blown) it is in very good condition.

I will post as I go along so far the power head was in a machine shop hone and corrected a single out of round cylinder. All cylinders are bored .30 over.

I will be experimenting with soda/media blasting starting with the Block and the rest of the parts, I opt out the acid bath method since I will still need to clean the rest of the parts for painting.

I am open for ideas on the painting and colors for both engine, LU, and cowling's.

If I bore anyone to death please pardon me, this for me personally it is a challenge whilst I know I am not re-inventing the wheel I am excited for now who knows down the road ?

Here she is all blown up!

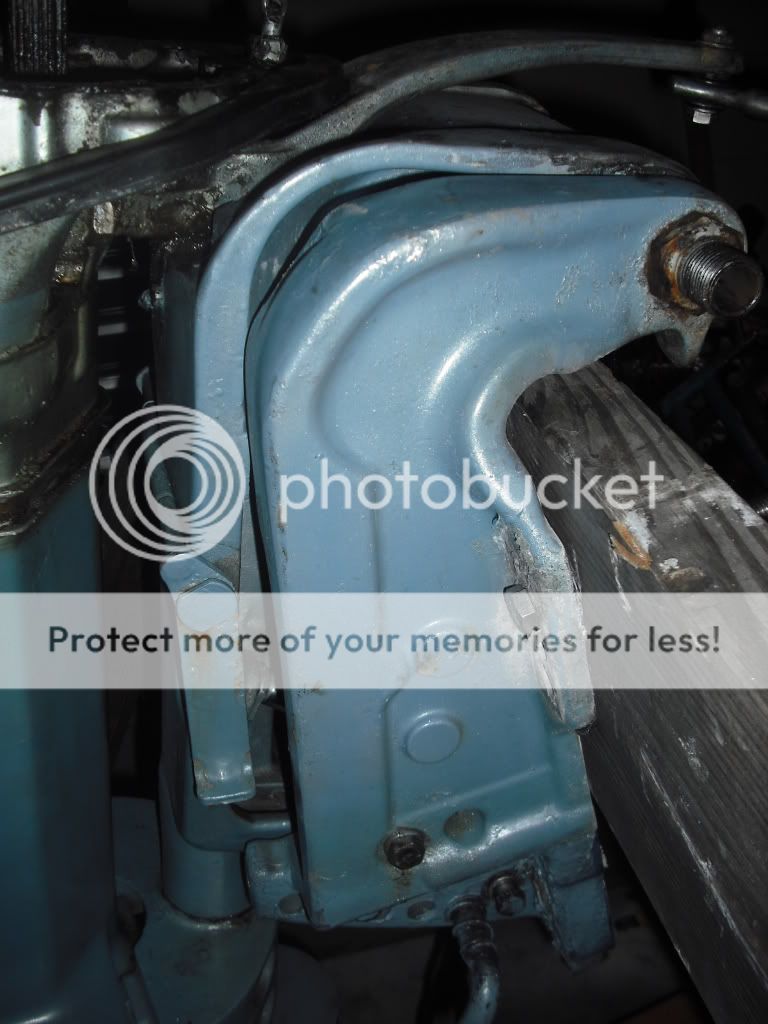

Same Block re-bore and so call clean I will soda blast it

Lots of corrosion around the outer sleeves or water way ..

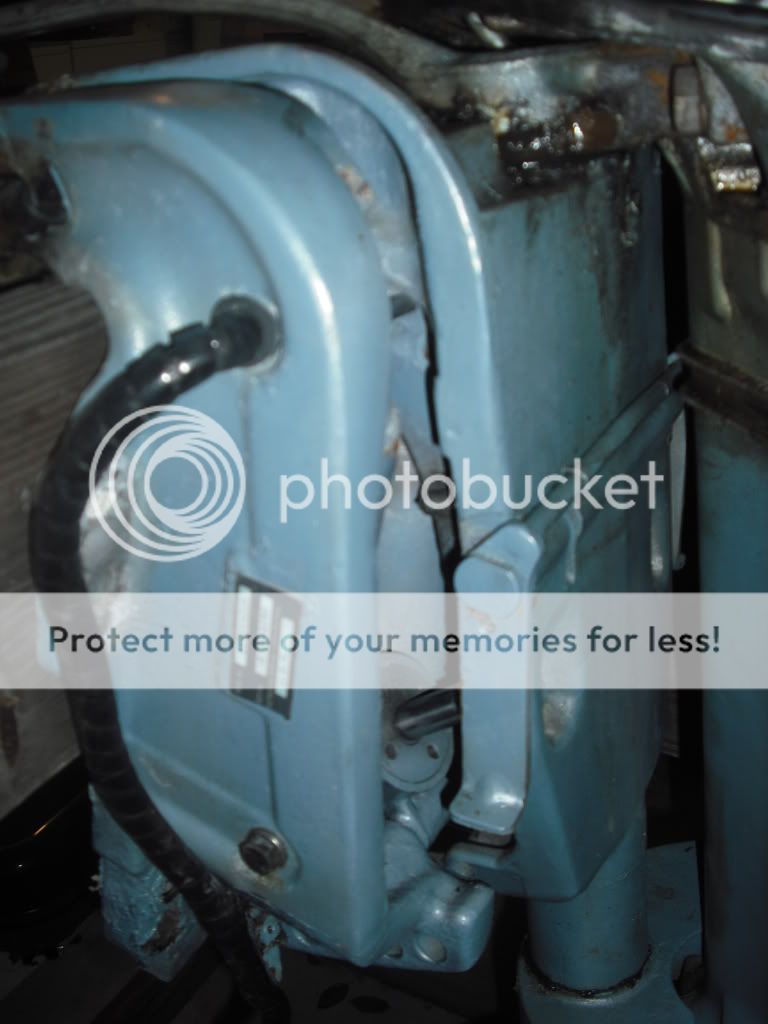

The engine shop shave both heads one is perfect one is like below I will not use this since I now have one from the donor motor in excellent condition

Perfect

Wish me luck..

I traded two older motors at the time with PowerHead Exchange out of Tampa and kept my blown power-head with this project in mind.

I will start rebuilding/assembly it from prop up. Trust me this is going to be long term project or if the 49ers sucks on Sundays then it will progress faster.

The objective is to apply what I have learned and hopefully own a engine I can be proud of, I have done my home work in regards to acquiring the parts and everything plus sum for this project.

This weekend I hit jackpot with an identical year/make/model motor minus power head (blown) it is in very good condition.

I will post as I go along so far the power head was in a machine shop hone and corrected a single out of round cylinder. All cylinders are bored .30 over.

I will be experimenting with soda/media blasting starting with the Block and the rest of the parts, I opt out the acid bath method since I will still need to clean the rest of the parts for painting.

I am open for ideas on the painting and colors for both engine, LU, and cowling's.

If I bore anyone to death please pardon me, this for me personally it is a challenge whilst I know I am not re-inventing the wheel I am excited for now who knows down the road ?

Here she is all blown up!

Same Block re-bore and so call clean I will soda blast it

Lots of corrosion around the outer sleeves or water way ..

The engine shop shave both heads one is perfect one is like below I will not use this since I now have one from the donor motor in excellent condition

Perfect

Wish me luck..

Last edited:

. Like I said earlier though, the carbs will drive you nuts most likely. Most everybody I've talked to has had problems after building one of these V-4 loopers and had to re-jet the carbs to fatten em up on the main and intermediate, but lean it out at idle.

. Like I said earlier though, the carbs will drive you nuts most likely. Most everybody I've talked to has had problems after building one of these V-4 loopers and had to re-jet the carbs to fatten em up on the main and intermediate, but lean it out at idle.