ludacrous999b

Member

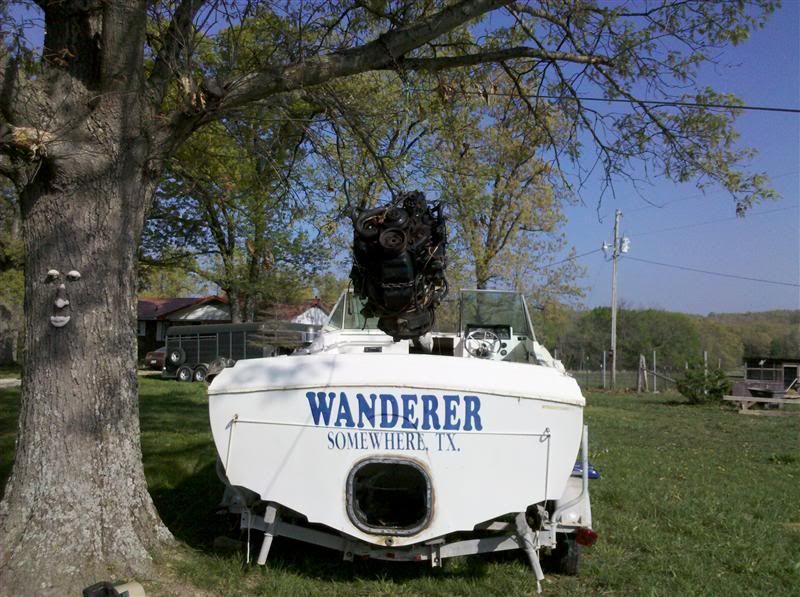

Well, more reading on here has taught me the value of inspection. When this engine comes out, the sterndrive is going to fall off and find it's self available for resale. After drilling into the transom I have discovered very damp wood and some rot. This has gone from a service the engine to get her running and float around a while to a rip out of the bastage and a transom rebuild.

Objective: Have the transom repaired and ready for an outboard when I return from Korea. I have all summer to complete the project so the only limiting factor is cost. Questions to follow...

Game plan to this moment...

1. Remove the engine and sterndrive and sell them for whatever I can get. Parts are hard to come by so maybe I can get at least a few bucks.

2. The thought kicking around in my head is to cut the cap about 1 foot from the transom, cut down the inside and across the deck, then just remove that portion of the cap. This will give me inspection of the inside of the hull to determine if I need to go further forward with a cap removal, and access to the rear of the boat for the transom work.

3... Guess I'll be researching designs that have been successful for outboard conversions. Cut the design and get my hands dirty with some glass work.

If I remove the entire cap I'll have a much easier time with wiring and interior work wont I? Previous experience is appreciated. Welcome to suggestions, advice and laughter.

Objective: Have the transom repaired and ready for an outboard when I return from Korea. I have all summer to complete the project so the only limiting factor is cost. Questions to follow...

Game plan to this moment...

1. Remove the engine and sterndrive and sell them for whatever I can get. Parts are hard to come by so maybe I can get at least a few bucks.

2. The thought kicking around in my head is to cut the cap about 1 foot from the transom, cut down the inside and across the deck, then just remove that portion of the cap. This will give me inspection of the inside of the hull to determine if I need to go further forward with a cap removal, and access to the rear of the boat for the transom work.

3... Guess I'll be researching designs that have been successful for outboard conversions. Cut the design and get my hands dirty with some glass work.

If I remove the entire cap I'll have a much easier time with wiring and interior work wont I? Previous experience is appreciated. Welcome to suggestions, advice and laughter.