Kracker Jack

God

Does anybody build rods on here? Im thinking about building a couple trolling rods just to say I did. My buddy has a wrapper set up and im gonna buy some blanks and give it a shot.

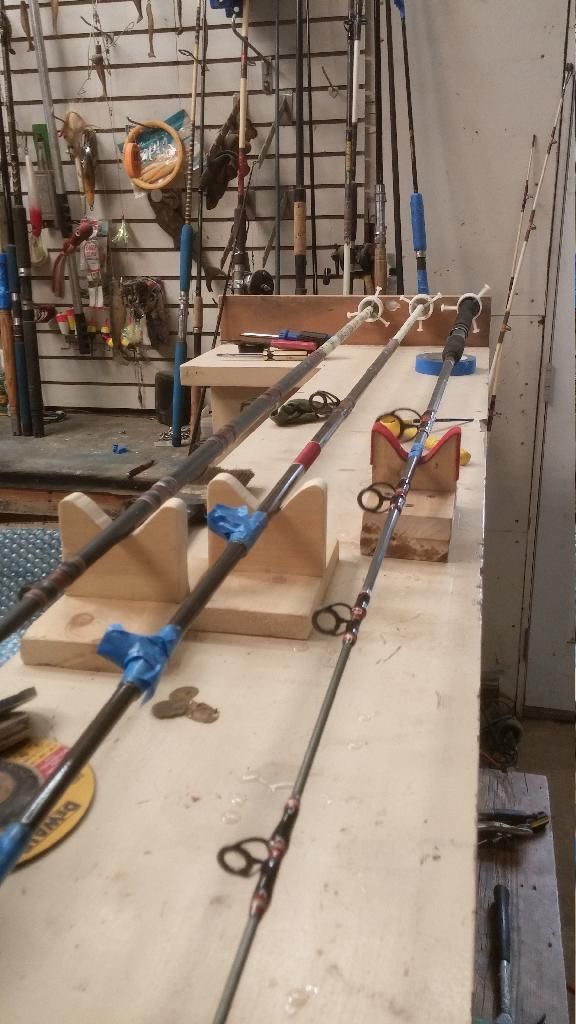

Im currently testing the waters by upgrading 4 daiwa beefsticks they seem to be decent heavy action blanks but the grips and reel seats are freaking junk. Im putting new tapered 12' EVA grips, Fuji hd reel seats and converting the butts to gimble. I bought 4 of these beefsticks at bass pro for super stupid cheap (on sale for like 14.00) like 6 years ago and they are tough as hell and troll my heavy Mojo and parachute rigs for striper nicely. They just have short grips.cheap reel seats and a rubber butt cap. So im gonna upgrade them.I will post pics of progress tomorrow.

Im currently testing the waters by upgrading 4 daiwa beefsticks they seem to be decent heavy action blanks but the grips and reel seats are freaking junk. Im putting new tapered 12' EVA grips, Fuji hd reel seats and converting the butts to gimble. I bought 4 of these beefsticks at bass pro for super stupid cheap (on sale for like 14.00) like 6 years ago and they are tough as hell and troll my heavy Mojo and parachute rigs for striper nicely. They just have short grips.cheap reel seats and a rubber butt cap. So im gonna upgrade them.I will post pics of progress tomorrow.