Kracker Jack

God

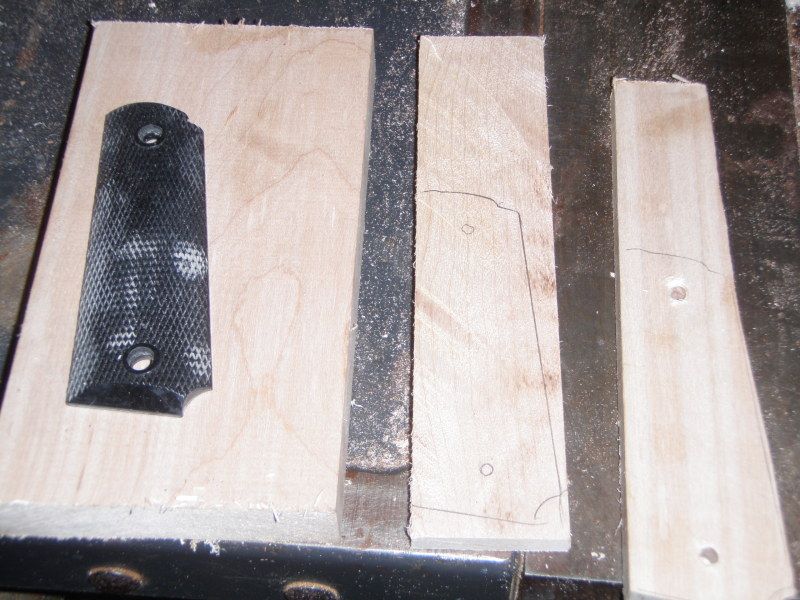

Here's a oak handle I made for my dads cleaver that he has kept by the fire place in the house since I was a baby. He use it to split cedar and other wood for kinlin. I noticed it missing from the house and I asked him were it was. He said the handle broke of. So as any son would do I wanted to see his cleaver by the fire place again, so I made the ole man a handle today. It's one piece oak and I even put his finger sizes in the handle. I gave it to him today and he got a little emotional. Love ya pop!!!

Last edited: