cjohnson82

New member

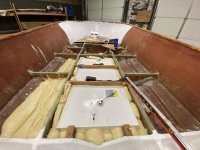

I’m new to forums and posting (so move the thread if needed) but I wanted to share my progress on my 1987 18’ “restomod”. I hope this can inspire some people to jump on their own projects and keep the momentum going. I started with a hull in good shape, but in pieces for $500 with the trailer. The previous owner started to do the work but lost interest after the transom was replaced and the stringers were worked on. I started by ripping out the ***8776;3 year old stringers that were there because they sloped towards the keel and would not have been a flat deck. Once I got it all cleaned out I started mocking up some marine grade 3/8” ply and building a new, much stronger framing system. I’m nearing completion of the frame and I’m ready to start glassing everything down to the hull. There’s a lot to learn about this but I’m doing my best with what i have. I’ve never done any fiberglassing nor boat work previously and I’m only 21 years old so bear with me! I will keep updating this thread if y’all would like to follow.

Attachments

-

00567B42-A4A1-4917-93B0-A3096BB27295.jpg23.4 KB · Views: 47

00567B42-A4A1-4917-93B0-A3096BB27295.jpg23.4 KB · Views: 47 -

8F4B660B-B615-4477-889A-AAF01A076998.jpg25 KB · Views: 43

8F4B660B-B615-4477-889A-AAF01A076998.jpg25 KB · Views: 43 -

91ACF8C2-0CB5-4801-9226-A3FB537AE9AD.jpg22.9 KB · Views: 39

91ACF8C2-0CB5-4801-9226-A3FB537AE9AD.jpg22.9 KB · Views: 39 -

7CFDFEAB-6E71-4798-BAF1-1CD63EF7F562.jpg25.7 KB · Views: 37

7CFDFEAB-6E71-4798-BAF1-1CD63EF7F562.jpg25.7 KB · Views: 37 -

68DAAD3B-513C-4D18-9C7F-4A8B5E254181.jpg23.9 KB · Views: 45

68DAAD3B-513C-4D18-9C7F-4A8B5E254181.jpg23.9 KB · Views: 45